The Dimension Bond Process

Dimension Bond Patented Technology

The Dimension Bond Corporation is the world leader in converting and providing dimensionally accurate surfaces using bonded bearing materials.

With Dimension Bond, surfaces are formed using a domestic and international patent-pending technology that permanently bonds bearing-grade material (or other functional/bonded material) to produce parts that have a derived dimension and are lubricated for the life of the unit.

Dimension Bond provides consistently accurate derived dimensions on almost any diameter or surface – rigid, flat or curved – by directly bonding bearing-grade composite materials to a surface with micron accuracy.

Dimension Bond Changes Surfaces for the Better

Compensating Dimension Bond℠

Using this process, each individual part receives the computer calculated thickness of bearing material it needs, thereby optimizing each part’s dimension and raising the CPK of the entire group of parts.

The completely computer-controlled CDB process adds or subtracts micron thick layers of the chosen materials being bonded to each individual part. Powerful algorithms in computer software continuously monitor the process, creating uniformity of the finished dimension irrespective of the tolerance of +/- 5 microns (+/- 0.0002”) from parts that started with tolerances as wide as +/- 25 microns (+/- 0.001”). Each out-of-tolerance part (parts that might otherwise be scrapped) is transformed into a totally in-specification, lubricated-for-life part.

Equal Dimension Bond℠

Using this process, all parts receive an equal thickness of bearing material bonded to each part, thereby maintaining the original dimensional CPK.

Equal Dimension Bond (EDB) offers the same amount of bearing-grade composite coating (or conventional lubricant coating) to each part.

Through use of the EDB Process, the dimensional distribution is enhanced to improve the finished lot’s CPK. We do this by adding either more or less material to all the parts, thereby improving the CPK for the entire individual lot. This is a no cost option.

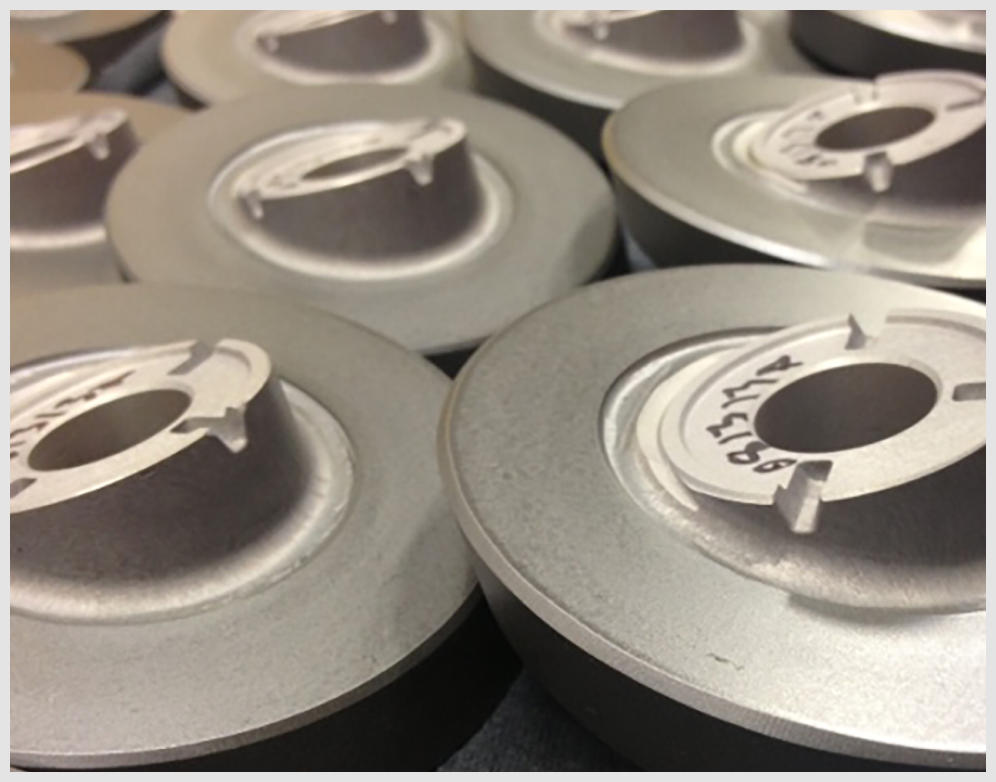

Conventional PTFE Wear Band for Pistons

- Finished OD Tolerance of +/- 50 Microns

- Requires Purchase and Inventory of Banding

- Requires Secondary Operations

- Banding Can Dislodge or Shift

- Potential for Uncontrolled Leak Paths

Dimension Bond Composite Direct Bonded Wear Band

- Tolerance +/- 10 Microns

- Wear Band Assembly Eliminated

- Machining of Grooves Eliminated

- Banding Materials Purchases Eliminated

- Larger Baring Surface Area

- No Banding to Dislodge, Shift, Split, or Tear

- No Uncontrolled Leak Paths

- Allows for Shorter Overall Height & Less Metal Cost

- Larger Diameter Valve Face Area for Design

- Reduced Dead Length

- Ease of Assembly into Pressure Tube

- Greater Wear Resistance with Lower Friction

Yoke Bearing Application

| Conventional Bushing | Dimension Bond Direct Bonded Composite |

| Tolerance of +/- 30 Microns | Tolerance +/- Microns |

| Purchase and Inventory of Bushings Required | Bushing Inventory Eliminated |

| Requires Assembly and Staking of Bushings | Assembly Operations Eliminated |

| Bushings Can Dislodge or Shift | Will not Dislodge or Shift |

| Can Require Secondary Operations | Full-Contact Bearing Surface |

| Greater Wear Resistance with Lower Friction | |

| Higher Temperature Resistance | |

| Glass Filled Plastics, Zinc and Powdered Metal – All successfully DB Processed |

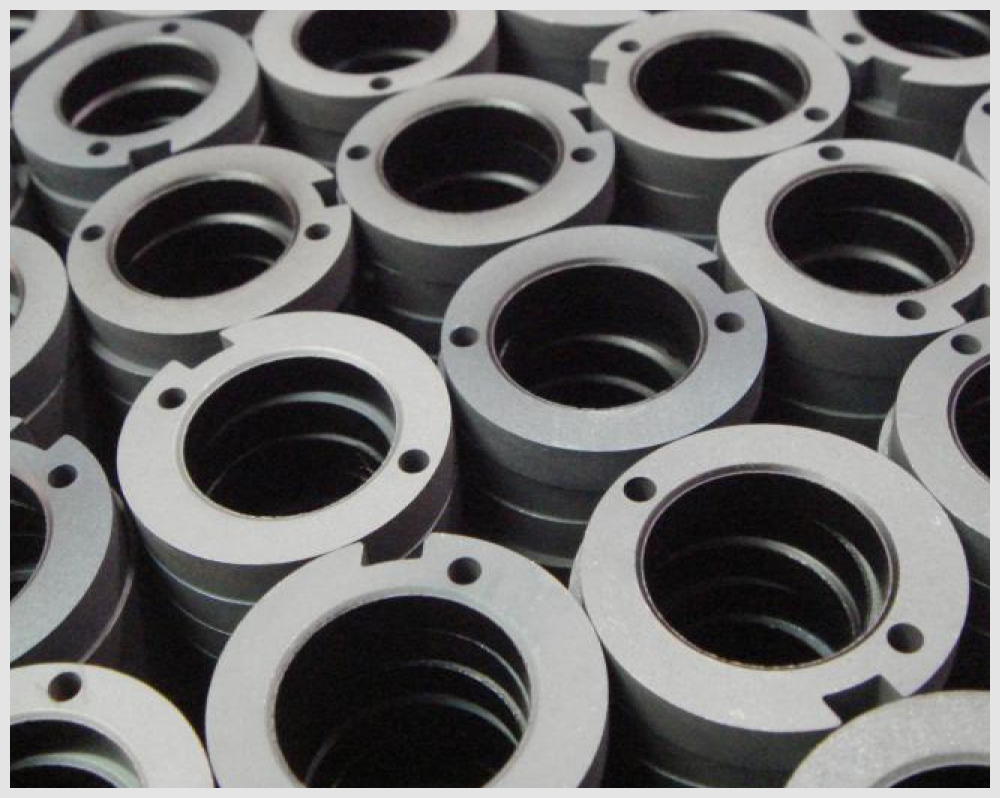

Rod Guide Application

| Conventional Split Bushing | Dimension Bond Direct Bonded Composite |

| Tolerance of +/- 40 Microns | Tolerance +/- 10 Microns |

| Purchase and Inventory of Bushings Required | Bushing Inventory Eliminated |

| Requires Secondary Operations | Secondary Machining or Bore Qualifying Eliminated |

| Bushing Requires Insert and Staking Operation | Longer, Larger Bearing Surface Area |

| Bushing can Dislodge or Shift | No Split Bushing to Dislodge |

| Uncontrolled Leak Paths | No Uncontrolled Leak Paths |

| Assembly Operations Eliminated | |

| Simplified Bore Design for Tooling Ease | |

| Higher Temperature Resistance | |

| Allows for Tighter Design Tolerances | |

| Oil Seal Push Out Eliminated |

Our Processes = Proven Technology

Our Customers (AS9100D with ISO 9001 and OEMs) demand top quality solutions. Dimension BondSM Two-Dimension Processes have solved their engineering and purchasing deeds.

Contact Us today so we can get started on a solution that will save you money while improving your product.